Abstract: Combined with the case of OCH in Sri Lanka, the reinforcement treatment technology of plastic drainage board method in soft foundation treatment is introduced, and the technical measures for construction quality control are elaborated.

Key words: soft ground treatment drainage board construction technology

- Project overview

The OCH project in Sri Lanka is the first construction part of the Colombo Outer Ring Road (OCH) project, connecting the Southern Transport Development Project (STDP) and the A4 Interchange (K27+900). The road is 11 kilometers long, and the road is designed as two-way four-lane road. The width of the top surface of the roadbed is 24.5m, and it will be expanded to six lanes in the future.

The whole line includes an interchange, a 3.255-kilometer-long viaduct (K18+440~K21+695), a highway bridge, 10 flyover bridges, 20 box culverts, and 12 pipe culverts.

According to geological survey, the project is located in a swamp area, and the geological structure from top to bottom is silt layer, clay layer, sand layer, and strongly weathered rock. The thickness of the silt layer is generally 2.5-3m. Therefore, the project is mostly located in the soft soil area, and the soft soil has the following characteristics.

- High natural water content and large void ratio.

- Poor water permeability.

- High compressibility.

- Low shear strength.

- Significant rheology.

Based on the above characteristics of the foundation soil of the project, and according to the conceptual design drawings provided by the owner, the soft soil foundation treatment methods of the project mainly include:

Type A: pilot layer + gravel cushion,

Type B: pilot layer + gravel cushion + geotechnical engineering Cloth,

C type: pilot layer + gravel cushion + drainage board + geotextile,

I type: pilot layer + gravel cushion + drainage board,

J type: sand replacement + drainage board + gravel cushion + geotextile,

H type : Six methods such as excavation and replacement.

Therefore, according to the above soft ground treatment types, except for types A, B, and H that do not use drainage boards, the rest include drainage board construction. The subgrade length (including ramp + approach line) that requires soft foundation treatment for the OCH project is about 8.7 kilometers in total, but the subgrade length that requires drainage board treatment is 6.2 kilometers, accounting for about 70% of the soft foundation treatment. Therefore, drainage board treatment is the main method of soft foundation treatment in this project. The following is an introduction to the construction technology of plastic drainage board treatment combined with engineering practice.

Second, the reinforcement principle and characteristics of the plastic drainage board method

- Process flow of plastic drainage board method

- Reinforcement principle of plastic drainage board method

The plastic drainage board method is a form of drainage consolidation method. The drainage consolidation method is to first set up vertical drainage bodies such as plastic drainage boards in the foundation, and then use the upper subgrade filling and surcharge preloading to make the pore water in the soil discharge from the gravel cushion through the drainage boards. The method of gradually consolidating the soft foundation soil and gradually subsiding the foundation, thereby improving the strength of the foundation. This method is one of the effective methods to deal with soft soil foundation, and it can solve the following two problems:

- Settlement problem, so that the settlement of the roadbed is mostly or basically completed during the filling of the roadbed and surcharge preloading, so that the roadbed will not produce uneven settlement.

- Stability issues, accelerate the growth of the shear strength of the foundation soil, thereby improving the bearing capacity and stability of the foundation.

- Characteristics of the plastic drainage board method

According to the experience in the construction process, the plastic drainage board makes up for the shortcomings of other soft foundation treatment methods, and has the following salient features in the construction process

- The plastic drainage board is mass-produced by the manufacturer. The material is uniform and reliable, and the drainage effect is stable. ;

- The plastic drainage board material has certain strength and elongation, and has a strong ability to adapt to foundation deformation;

- The section size of the plastic drainage board is small, which is convenient for construction operation, has little disturbance to the foundation soil when inserted, and has good continuity;

- The construction machinery is light and can be constructed on ultra-soft ground; the construction speed is fast and the project cost is cheap.

- Construction machinery and materials

- Construction machinery and equipment

The design insertion depth of the engineering plastic drainage board is 4-6m, and the engineering volume is about 1 million meters. The construction adopts PC-300 or PC-400 crawler-type special static pressure inserting machine, which is assembled by PC-300 or PC-400 excavator and inserting plate frame. The plug-in machine has flexible operation, convenient walking, less disturbance to the ground, fast insertion speed, convenient construction, and easy construction quality assurance.

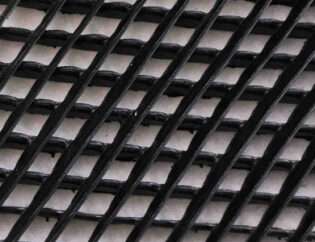

- Selection of Plastic Drainage Board Materials

According to the requirements of technical specifications, the plastic drainage board used in this project should have corrosion resistance and sufficient flexibility, and it will not crack when it is curled or folded back. Its technical indicators must meet the design requirements, and it must be inspected by the supervisory engineer after entering the site before it can be put into use.

- Construction Quality Control

In order to ensure the construction quality of the project and ensure the effect of soft foundation treatment, the construction quality is mainly controlled from the following aspects during the construction process:

- Firstly, fill in a 50cm pilot layer on the original ground after cleaning the surface, level it with a bulldozer or excavator and must pass the acceptance of the engineer.

- Use a bulldozer to lay a 20cm gravel cushion, and level it to ensure that the plug-in machine can smoothly insert the drainage board on the work site. The laid gravel cushion does not need to be compacted with a road roller.

- Stake out the insertion position of the plastic drainage board strictly according to the position and spacing designed in the construction drawing, and mark it with lime, strictly control the spacing of the plastic drainage board, and strictly prohibit random insertion.

- The drainage board purchased and brought into the site should be covered on site, and should avoid direct sunlight and long-term exposure to the air for aging.

- After the plastic drainage board enters the construction site, it must be sampled and inspected by the supervisory engineer and qualified. The technical indicators can only be used after meeting the design requirements. Before laying, it should be inspected by a special person, and the damaged and polluted parts should be cut off.

- The anchor plate should be matched with the drainage plate and the casing to prevent the silt from entering the casing. Once found, it must be removed in time to prevent the friction between the plastic plate and the casing wall from increasing and causing the plastic plate to be taken out.

- In order to prevent silt from entering the board core to block the drainage channel, affect the drainage effect, and prevent the plastic drainage board from being taken out, the plastic drainage board at the bottom end should be folded back to a certain length, and it should be reliably connected with the anchor board, and the anchor board is sealed with the lower port of the conduit Be strict.

- In order to ensure the accuracy of the record of the depth of the plastic drainage board, there should be an obvious footage mark on the plug machine tower.

- During the installation process, when the length of the plastic drainage board is not enough and needs to be extended, it must be carried out in accordance with the technical specifications or with the approval of the engineer.

- Strictly monitor the penetration depth of the plastic drainage board. If the driving depth is obviously less than the design value, or there are solid objects under the foundation, the drainage board at this point should be discarded, and repaired at the nearest place under the instruction of the supervisory engineer.

- In the process of inserting the plastic drainage board, there must be a special person to make various records. The inspection standards and inspection methods for the construction quality of plastic drainage boards are shown in Table 1.

Table 1. Permissible deviation, inspection quantity and method of plastic drainage board

| serial number | project | Allowable deviation | Inspection unit | quantity | Testing method |

| 1 | plane position | ±100mm | each drain board | random check | Use the total station to release the area of the drainage board, then carry out manual stakeout according to the points on the drawing, and mark it with lime. |

| 2 | exposed length | ±50mm | Check piece by piece | Measure with a steel ruler |

- After each drainage board is inserted, the exposed drainage board shall not be polluted. Workers should be sent to cover with gravel in time to connect it with the gravel cushion to ensure unimpeded drainage and prevent damage to the drainage board during subsequent construction.

- Problems and countermeasures in construction

Through the practice of drainage board construction in this project, it is found that there are still some difficulties in quality control in the construction technology of plastic drainage board method.

- The length of the heel strap is too long

According to on-site observation and analysis, the main reason is that the model and quality of some anchor plates have certain defects. During the insertion process, the anchor

The belt breaks so that the plastic board is carried out, which affects the progress of inserting the drainage board. Therefore, in the process of laying plastic drainage boards, it is necessary to check the anchor boards in time according to the actual situation, and replace the defective anchor boards in time.

- Construction effect

It has been proved by practice that at the beginning of the construction of the drainage board, due to the unfamiliarity with the technology of inserting the drainage board, the workers' operation

For other reasons, only 300 points can be inserted and played every day, with a total length of about 1200 meters. With the continuous improvement of the construction technology of the drainage board, such as reasonably arranging the direction of the plugging machine, familiarizing with the plugging radius of the plugging machine, etc., and after standardizing the operation of the construction personnel on site, nearly 600 points can be inserted and punched every day, and the total length can be increased. Reaching about 2500 meters, thus greatly improving the construction speed and shortening the construction period of soft foundation treatment.

- Exposed length

After the construction of each drainage board is completed, it must be manually cut by the construction personnel. According to the design requirements, the exposed length must be

Guaranteed to be within 30cm (±5cm). Due to the operating proficiency of the construction personnel, some exposed lengths exceeded the allowable range during construction, which caused the phenomenon of repairing drainage boards in the vicinity, which had a certain impact on the construction quality. Therefore, after instructing the construction personnel on the correct cutting method and making the cutting ruler according to the design allowable value requirements, the situation that the exposed length exceeds the standard has been avoided.

- Conclusion

During the soft foundation treatment process of plastic drainage boards in this project, due to sufficient construction preparations, sound systems, and strict technical measures for construction process control, this method fully reflects the low labor intensity, fast construction speed, and soft foundation in the construction. The effect of base treatment is quick, and the construction quality is more guaranteed.